Code Context ?>

<?php

$url = htmlspecialchars($_SERVER['HTTP_REFERER']);

$viewFile = '/home/flexiborvx/www/app/View/Produits/index.ctp'

$dataForView = array(

'Categories' => array(

(int) 0 => array(

'Scategorie' => array(

[maximum depth reached]

),

'Categorie' => array(

[maximum depth reached]

),

'Souscategorie' => array([maximum depth reached]),

'Produit' => array(

[maximum depth reached]

),

'Media' => array([maximum depth reached])

)

),

'produit' => array(

(int) 0 => array(

'Produit' => array(

[maximum depth reached]

),

'Scategorie' => array(

[maximum depth reached]

),

'Souscategorie' => array(

[maximum depth reached]

),

'ImageProduit' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

),

(int) 1 => array(

'Produit' => array(

[maximum depth reached]

),

'Scategorie' => array(

[maximum depth reached]

),

'Souscategorie' => array(

[maximum depth reached]

),

'ImageProduit' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

),

(int) 2 => array(

'Produit' => array(

[maximum depth reached]

),

'Scategorie' => array(

[maximum depth reached]

),

'Souscategorie' => array(

[maximum depth reached]

),

'ImageProduit' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

),

(int) 3 => array(

'Produit' => array(

[maximum depth reached]

),

'Scategorie' => array(

[maximum depth reached]

),

'Souscategorie' => array(

[maximum depth reached]

),

'ImageProduit' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

)

),

'types' => array(

(int) 1 => 'FLEXI BORDJ ',

(int) 2 => 'FLEXI BORDJ PLUS'

),

'Cat' => array(

(int) 0 => array(

'Categorie' => array(

[maximum depth reached]

),

'Type' => array(

[maximum depth reached]

),

'Scategorie' => array(

[maximum depth reached]

),

'Media' => array([maximum depth reached])

),

(int) 1 => array(

'Categorie' => array(

[maximum depth reached]

),

'Type' => array(

[maximum depth reached]

),

'Scategorie' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

),

(int) 2 => array(

'Categorie' => array(

[maximum depth reached]

),

'Type' => array(

[maximum depth reached]

),

'Scategorie' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

),

(int) 3 => array(

'Categorie' => array(

[maximum depth reached]

),

'Type' => array(

[maximum depth reached]

),

'Scategorie' => array(

[maximum depth reached]

),

'Media' => array([maximum depth reached])

),

(int) 4 => array(

'Categorie' => array(

[maximum depth reached]

),

'Type' => array(

[maximum depth reached]

),

'Scategorie' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

),

(int) 5 => array(

'Categorie' => array(

[maximum depth reached]

),

'Type' => array(

[maximum depth reached]

),

'Scategorie' => array([maximum depth reached]),

'Media' => array([maximum depth reached])

)

),

'sociales' => array(

(int) 0 => array(

'Sociale' => array(

[maximum depth reached]

)

),

(int) 1 => array(

'Sociale' => array(

[maximum depth reached]

)

),

(int) 2 => array(

'Sociale' => array(

[maximum depth reached]

)

),

(int) 3 => array(

'Sociale' => array(

[maximum depth reached]

)

)

),

'contact' => array(

'Contact' => array(

'id' => '7',

'nom' => 'FLEXI BORDJ',

'email' => 'contact@flexibordj.com',

'adresse' => 'lot 12 hectars Rue B N°17 Bordj Bou Arreridj',

'map' => '36.068495, 4.746334',

'fax' => '',

'tel1' => '',

'tel2' => '',

'tel3' => '',

'mob1' => '',

'mob2' => '0770281512',

'mob3' => '0770959812',

'date_ajout' => '2017-07-02'

)

),

'apropos' => array(

'Apropo' => array(

'id' => '1',

'resume' => 'La Société FLEXI BORDJ à été crée en 1999 Sont activité Principale se Réside a la Fabrication

En série de Flexibles Hydrauliques et Industrielle .Destines au Marché de la Première Monte.

Reconnue tant au Niveau de BORDJ BOU ARRARIDJ que Nationale et Régional

Cette Evolution est à L’origine du au Renouvellement de nos Equipements Modernes

Fabriqué Par UNIFLEX GERMMANY.

Notre Société est Spécialisée de la Fabrication et la Commercialisation de Flexible Hydraulique Equipée ainsi les Composants Hydrauliques et Industrielles

Notre Politique Commerciale Basée sur la Qualité de nos Produits Notre Notion de Services

La Maîtressé de nos Proccèss de Fabrication Nous ont Permis de nous Développée et être Reconnus

En tant que Fournisseur chez un bon Nombre en Algérie

',

'detail' => '<p><span style="font-size:12px"><strong><a href="http://hydra-holding.com/hydra-connect/nos-produits/">Notre gamme complète</a>, combinée à notre polyvalence nous permet d’être présents dans <a href="http://hydra-holding.com/hydra-connect/nos-references/">différents domaines</a> :</strong></span><br />

<span style="font-size:14px">Matériels agricoles / travaux publics / industrie / manutention .<br />

Industrie minière, forestière et pétrolière .</span></p>

<p>FLEXI BORDJ MOBILE</p>

<p>Un Atelier Mobile Complet et très Fonctionnel nous Permet d’effectuée tous types de Dépannages</p>

<p>Sur Site a fin de Répondre a vos Problématique Techniques</p>

<p> <strong>FLEXI BORDJ </strong></p>

<p><strong> REACTIVITE – QUALITE – FLEXIBILITE </strong></p>

',

'resume1' => 'FLEXI BORDJ PLUS a été fondé en 2015 dans BORDJ BOU ARRERIDJ . Cette entreprise est un fournisseur pour le marché de tuyau et raccords hydraulique et pneumatique ainsi que un représentant et distributeur UNIFLEX spécialisé dans les machines industriels qui est aussi un partenaire préféré pour les usines des constructeurs de flexible .

',

'detail1' => '<h1><span style="font-family:Arial,Helvetica,sans-serif"><strong><span style="font-size:14px"><span style="color:#ff0000">Objectifs et visions</span></span></strong></span></h1>

<ol>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Polyvalence</strong><br />

<br />

Les presses pour flexibles UNIFLEX sont construites de manière modulaire. Il est ainsi toujours possible de réaliser les variantes les plus diverses pour satisfaire quasiment toutes les exigences et applications souhaitées.</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">Les observations du marché et les analyses des besoins du client déterminent le développement de nouveaux modules et modèles. </span></p>

<p> </p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Fiabilité</strong><br />

<br />

Les presses pour flexibles UNIFLEX sont conçues pour fonctionner de nombreuses années. La précision et la qualité de tous les produits UNIFLEX fixent les</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">critères à respecter au niveau international. Le retour des clients est enregistré afin de pouvoir déduire et</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">mettre en application des possibilités d’optimisation relatives au fonctionnement et à la disponibilité.</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">/></span></p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Innovation</strong><br />

<br />

C’est dans un dialogue permanent avec les clients</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">qu’UNIFLEX continue résolument de développer les produits existants – l’expérience est mise au profit de</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">la pratique. Les besoins du marché, les possibilités techniques innovantes et un travail approfondi de</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">recherche fondamentale donnent naissance à des produits toujours novateurs et révolutionnaires dans le</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">domaine de l'assemblage de flexibles. </span><br />

</p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Service</strong><br />

<br />

Chaque jour,</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">plus de 40 années d’expérience et de compétences sont redéfinies et transmises aux clients par UNIFLEX.</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">L’équipe UNIFLEX est chargée du conseil individuel relatif aux produits ainsi que de l’accompagnement</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">des clients, et fournit des prestations de service qualifiées telles que formations, travail logistique,</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">présentations de test et démonstration. Ainsi, vous pouvez vous concentrer sur votre activité principale, à</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">savoir la fabrication de tuyaux flexibles, en utilisant les meilleures machines disponibles sur le</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">marché.</span><br />

</p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Orientation vers l’utilisateur</strong><br />

<br />

Un contact permanent</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">avec le client offre la possibilité de mettre en application les expérience issues de la pratique en matière</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">de manipulation et d’opérabilité, de sécurité et d’ergonomie dans le futur développement de série.</span></p>

</li>

</ol>

<p> </p>

',

'image' => 'apropos1505333254.jpg',

'image2' => 'aproposs1505333254.jpg'

),

'Media' => array()

),

'liens' => 'http://flexibordj.com',

'destintaires' => array(

'contact@flexibordj.com' => 'Contact'

),

'menus' => array(

(int) 0 => array(

'Menu' => array(

[maximum depth reached]

)

),

(int) 1 => array(

'Menu' => array(

[maximum depth reached]

)

),

(int) 2 => array(

'Menu' => array(

[maximum depth reached]

)

),

(int) 3 => array(

'Menu' => array(

[maximum depth reached]

)

),

(int) 4 => array(

'Menu' => array(

[maximum depth reached]

)

),

(int) 5 => array(

'Menu' => array(

[maximum depth reached]

)

),

(int) 6 => array(

'Menu' => array(

[maximum depth reached]

)

)

),

'lang' => 'fr'

)

$Categories = array(

(int) 0 => array(

'Scategorie' => array(

'id' => '15',

'nom' => 'Bancs d’épreuves',

'image' => '1499605282.png',

'categorie_id' => '6'

),

'Categorie' => array(

'id' => '6',

'nom_fr' => 'MACHINE UNIFLEX ',

'image' => 'FLEXI BORDJ.jpg',

'type_id' => '2',

'date_ajout' => '2017-06-19'

),

'Souscategorie' => array(),

'Produit' => array(

(int) 0 => array(

[maximum depth reached]

),

(int) 1 => array(

[maximum depth reached]

),

(int) 2 => array(

[maximum depth reached]

),

(int) 3 => array(

[maximum depth reached]

)

),

'Media' => array()

)

)

$produit = array(

(int) 0 => array(

'Produit' => array(

'id' => '286',

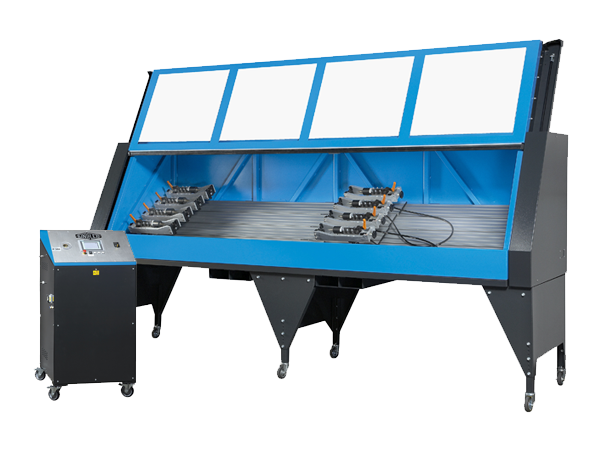

'nom' => 'Bancs d’épreuves P300',

'ref' => 'Bancs d’épreuves P300',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531255802.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p>Testing has never been easier and quicker. With the P300, you can perform precision tests of hoses of up to 2500 mm in length and with pressures up to 1000 bar.<br />

<br />

Test up to 120 hoses per hour, making use of 4 parallel test lines and our quick-clamping system. You can choose between automated and manual setup mode. The P300 comes with a number of standard features such as an internal lighting and a portable power aggregate, and caters for individual test logging</p>

<p><strong>CARACTERISTIQUES TECHNIQUES </strong>:</p>

<table border="1" cellpadding="0" cellspacing="0">

<tbody>

<tr>

<td style="height: 39px; width: 141px; background-color: rgb(0, 153, 255);">

<p><span style="color:#000000"><strong>Modell:</strong></span></p>

</td>

<td style="height: 39px; width: 149px; background-color: rgb(0, 153, 255);">

<p><span style="color:#000000"><strong>P 300</strong></span></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Control</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Control C.2 + Touch</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Drive</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>Hydraulic aggregate 3kW with intesifier</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Flow</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>13 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>400-50-3 (VAC)</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>3750 x 2400 x 870</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Tank dimension closed (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>3750 x 1450 x 870</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Aggregate dimension (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>830 x 740 x 1340</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>140.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>70</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Paint</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>RAL 5012, RAL 7021</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test Medium</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Test Oil</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Max. hose length</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>2500 mm</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>1000 Kg empty</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight aggregate</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>200 Kg empty</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="color:#0099ff"><strong>Avantages : </strong></span></p>

<p>- Réservoir intégré avec filtre</p>

<p>- Universal</p>

<p>- CE Conforme</p>

<p>- 2 ans de garantie</p>

<p> </p>

<p><span style="color:#0099ff"><strong>Package et accessoires :</strong></span></p>

<p>Développez cette machine à tout moment en utilisant les accessoires suivants:</p>

<p><strong>BTR Ctrl C/UTS</strong></p>

',

'fichier' => '1531255802.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

'Scategorie' => array(

'id' => '15',

'nom' => 'Bancs d’épreuves',

'image' => '1499605282.png',

'categorie_id' => '6'

),

'Souscategorie' => array(

'id' => null,

'nom' => null,

'image' => null,

'scategorie_id' => null

),

'ImageProduit' => array(),

'Media' => array()

),

(int) 1 => array(

'Produit' => array(

'id' => '285',

'nom' => 'Bancs d’épreuves P200',

'ref' => 'Bancs d’épreuves P200',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531247260.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p>Der The P 200 test bench with digital Control B+ Touch control and tight clamping system makes testing not only easier and quicker but also extremely flexible. Enter all test parameters at the user-friendly menu control and save them, if required with the relevant product number.</p>

<p>The test parameters for a product can then be reloaded at the push of a button, reducing tooling time while ensure reproducibility.</p>

<p>The patented tight clamping system does away with screws and threaded adapters. Pressure testing reveals any defects in the material or assembly at the earliest possible time</p>

<p><strong>CARACTERISTIQUES TECHNIQUES </strong>:</p>

<table border="1" cellpadding="0" cellspacing="0">

<tbody>

<tr>

<td style="height: 39px; width: 141px; background-color: rgb(0, 153, 255);">

<p><strong>Modell:</strong></p>

</td>

<td style="height: 39px; width: 149px; background-color: rgb(0, 153, 255);">

<p><strong>P 160</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Control</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Control B + Touch</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Drive</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>Druckübersetzer / Intensifier</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Flow</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>5 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>7 bar, 20 Nl / min</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>1590 x 795 x 370</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test bench dimension (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>2210 x 950 x 1325</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>100.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Alternative drive</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>0,38 kW</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>72</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Paint</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>RAL 5012 ; RAL 7021</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>210 Kg empty</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="color:#0099ff"><strong>avantage:</strong></span><br />

-universal</p>

<p>-Réservoir intégré avec filtre</p>

<p>- CE Conforme</p>

<p>- 2 ans de garantie <!--![endif]----></p>

<p> </p>

<p><span style="font-size:14px"><span style="color:#0099ff"><strong>Package et accessoires :</strong></span></span></p>

<p><br />

Un package inclut les machines sélectionnées incl. Accessoires.</p>

<p>P 200 Paquet = Machine + BDSP, HS 400, EM 10 l + DS + DSP</p>

',

'fichier' => '1531247260.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

'Scategorie' => array(

'id' => '15',

'nom' => 'Bancs d’épreuves',

'image' => '1499605282.png',

'categorie_id' => '6'

),

'Souscategorie' => array(

'id' => null,

'nom' => null,

'image' => null,

'scategorie_id' => null

),

'ImageProduit' => array(),

'Media' => array()

),

(int) 2 => array(

'Produit' => array(

'id' => '284',

'nom' => 'Bancs d’épreuves P160 Ecoline',

'ref' => 'Bancs d’épreuves P160 Ecoline',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531245590.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p>Testing has never been easier and quicker. With the P300, you can perform precision tests of hoses of up to 2500 mm in length and with pressures up to 1000 bar.<br />

<br />

Test up to 120 hoses per hour, making use of 4 parallel test lines and our quick-clamping system. You can choose between automated and manual setup mode. The P300 comes with a number of standard features such as an internal lighting and a portable power aggregate, and caters for individual test logging</p>

<p><span style="color:#0099ff"><strong>CARACTERISTIQUES TECHNIQUES </strong></span></p>

<table align="left" border="1" cellpadding="0" cellspacing="0" style="width:459px">

<tbody>

<tr>

<td style="background-color:#0099ff; height:1px">

<p><strong>Modell:</strong></p>

</td>

<td style="background-color:#0099ff; height:1px">

<p><strong>P 300</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:1px">

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Control</strong></p>

</td>

<td style="height:1px">

<p><strong>Control B + Touch</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Drive</strong></p>

</td>

<td style="height:1px">

<p><strong>Hydraulic aggregate 3kW with intesifier</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Flow</strong></p>

</td>

<td style="height:1px">

<p><strong>13 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:1px">

<p><strong>400-50-3 (VAC) </strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:1px">

<p><strong>3750 x 2400 x 870 </strong></p>

</td>

</tr>

<tr>

<td style="height:37px">

<p><strong>Tank dimension closed (mm)</strong></p>

</td>

<td rowspan="1" style="height:1px">

<p><strong>3750 x 1450 x 870 </strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Test bench dimension (mm)</strong></p>

</td>

<td style="height:1px">

<p><strong>-</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Aggregate dimension (mm</strong></p>

</td>

<td style="height:1px">

<p><strong>830 x 740 x 1340</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td rowspan="1" style="height:1px">

<p><strong>140.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Alternative drive</strong></p>

</td>

<td rowspan="1" style="height:1px">

<p><strong>-</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:1px">

<p><strong>70</strong></p>

</td>

</tr>

<tr>

<td style="height:59px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:59px">

<p><strong>1000 Kg</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Weight aggregate</strong></p>

</td>

<td style="height:1px">

<p><strong>200 Kg</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="color:#0099ff"><strong>Avantages : </strong></span></p>

<p>-Sans lubrification</p>

<p>-Universal</p>

<p>-CE Conforme</p>

<p>-2 ans de garantie</p>

<h3><span style="color:#0099ff"><strong>Package et accessoires</strong></span></h3>

<p>Développez cette machine à tout moment en utilisant les accessoires suivants:</p>

<h4> UTS</h4>

<h4><strong><a href="https://www.uniflex-hydraulics.com/fr/produits/accessoires/btr-ctrl-c/?tt_products%5BbackPID%5D=44"><span style="color:#000000">BTR Ctrl C</span></a></strong></h4>

<p> </p>

',

'fichier' => '1531246295.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

'Scategorie' => array(

'id' => '15',

'nom' => 'Bancs d’épreuves',

'image' => '1499605282.png',

'categorie_id' => '6'

),

'Souscategorie' => array(

'id' => null,

'nom' => null,

'image' => null,

'scategorie_id' => null

),

'ImageProduit' => array(),

'Media' => array()

),

(int) 3 => array(

'Produit' => array(

'id' => '283',

'nom' => 'Bancs d’épreuvesP160',

'ref' => 'Bancs d’épreuvesP160',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531235118.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p> </p>

<p>Hose lines that cannot withstand the high pressure for which they are designed can cause serious damage, resulting in high costs - often higher than the price of a test bench.</p>

<p><strong>Why take a risk that can be easily avoided?</strong></p>

<p>By testing the quality of your products, you opt for safety.</p>

<p>The P 160 workshop test bench allows for the efficient and safe final inspection and testing of hose lines. It is easy to operate and quickly become part of your routine procedures.</p>

<p><span style="color:#0099ff"><strong>CARACTERISTIQUES TECHNIQUES </strong>:</span></p>

<table border="1" cellpadding="0" cellspacing="0">

<tbody>

<tr>

<td style="height:39px; width:141px">

<p><strong>Modell:</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>P 160</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Control</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Manual</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Drive</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>Druckübersetzer / Intensifier</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Flow</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>1,1 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>7 bar, 20 Nl / min</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>1590 x 795 x 370</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test bench dimension (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>2210 x 950 x 1325</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>100.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Alternative drive</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>0,38 kw, 400V 50 Hz 3Ph</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>72</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Paint</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>RAL 5012, RAL 7021</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>210 Kg empty</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="font-size:14px"><span style="color:#0099ff"><strong>Avantages : </strong></span></span></p>

<p>-Réservoir intégré avec filtre</p>

<p>- Universal</p>

<p>- CE Conforme</p>

<p>- 2 ans de garantie <!--![endif]----></p>

<p><span style="color:#0099ff"><span style="font-size:14px"><strong>Package et accessoires :</strong></span></span></p>

<p><strong> </strong></p>

<p>Un package inclut les machines sélectionnées incl. Accessoires.</p>

<p>P 160 Paquet = Machine + adaptateur « Steck O » 405.901 et 405.902, EM 10 l</p>

<p> </p>

',

'fichier' => '1531235118.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

'Scategorie' => array(

'id' => '15',

'nom' => 'Bancs d’épreuves',

'image' => '1499605282.png',

'categorie_id' => '6'

),

'Souscategorie' => array(

'id' => null,

'nom' => null,

'image' => null,

'scategorie_id' => null

),

'ImageProduit' => array(),

'Media' => array()

)

)

$types = array(

(int) 1 => 'FLEXI BORDJ ',

(int) 2 => 'FLEXI BORDJ PLUS'

)

$Cat = array(

(int) 0 => array(

'Categorie' => array(

'id' => '1',

'nom_fr' => 'HYDRAULIQUE',

'image' => '1497872692.jpg',

'type_id' => '1',

'date_ajout' => '2017-06-19'

),

'Type' => array(

'id' => '1',

'nom_fr' => 'FLEXI BORDJ '

),

'Scategorie' => array(

(int) 0 => array(

[maximum depth reached]

),

(int) 1 => array(

[maximum depth reached]

),

(int) 2 => array(

[maximum depth reached]

),

(int) 3 => array(

[maximum depth reached]

),

(int) 4 => array(

[maximum depth reached]

)

),

'Media' => array()

),

(int) 1 => array(

'Categorie' => array(

'id' => '2',

'nom_fr' => 'PNEUMATIQUE',

'image' => '2.jpg',

'type_id' => '1',

'date_ajout' => '2017-06-19'

),

'Type' => array(

'id' => '1',

'nom_fr' => 'FLEXI BORDJ '

),

'Scategorie' => array(),

'Media' => array()

),

(int) 2 => array(

'Categorie' => array(

'id' => '5',

'nom_fr' => 'DISTRIBUTION',

'image' => 'FLEXI BORDJ1.jpg',

'type_id' => '2',

'date_ajout' => '2017-06-19'

),

'Type' => array(

'id' => '2',

'nom_fr' => 'FLEXI BORDJ PLUS'

),

'Scategorie' => array(),

'Media' => array()

),

(int) 3 => array(

'Categorie' => array(

'id' => '6',

'nom_fr' => 'MACHINE UNIFLEX ',

'image' => 'FLEXI BORDJ.jpg',

'type_id' => '2',

'date_ajout' => '2017-06-19'

),

'Type' => array(

'id' => '2',

'nom_fr' => 'FLEXI BORDJ PLUS'

),

'Scategorie' => array(

(int) 0 => array(

[maximum depth reached]

),

(int) 1 => array(

[maximum depth reached]

),

(int) 2 => array(

[maximum depth reached]

),

(int) 3 => array(

[maximum depth reached]

),

(int) 4 => array(

[maximum depth reached]

),

(int) 5 => array(

[maximum depth reached]

),

(int) 6 => array(

[maximum depth reached]

),

(int) 7 => array(

[maximum depth reached]

),

(int) 8 => array(

[maximum depth reached]

),

(int) 9 => array(

[maximum depth reached]

),

(int) 10 => array(

[maximum depth reached]

)

),

'Media' => array()

),

(int) 4 => array(

'Categorie' => array(

'id' => '76',

'nom_fr' => 'INDUSTRIELS',

'image' => 'Fluid_IndSchlaeuche_750x400.jpg',

'type_id' => '1',

'date_ajout' => '2017-08-20'

),

'Type' => array(

'id' => '1',

'nom_fr' => 'FLEXI BORDJ '

),

'Scategorie' => array(),

'Media' => array()

),

(int) 5 => array(

'Categorie' => array(

'id' => '77',

'nom_fr' => 'ATELIER MOBILE',

'image' => '1504083554.jpg',

'type_id' => '1',

'date_ajout' => '2017-08-30'

),

'Type' => array(

'id' => '1',

'nom_fr' => 'FLEXI BORDJ '

),

'Scategorie' => array(),

'Media' => array()

)

)

$sociales = array(

(int) 0 => array(

'Sociale' => array(

'id' => '17',

'nom' => 'Facebook',

'lien' => 'http://facebook.com',

'image' => 'fa fa-facebook ',

'color' => '3b5998',

'date_ajout' => '2016-05-02'

)

),

(int) 1 => array(

'Sociale' => array(

'id' => '18',

'nom' => 'Youtube',

'lien' => 'http://youtube.com',

'image' => 'fa fa-youtube',

'color' => 'FF3333',

'date_ajout' => '2016-07-24'

)

),

(int) 2 => array(

'Sociale' => array(

'id' => '19',

'nom' => 'Google+',

'lien' => 'http://google.com',

'image' => 'fa fa-google-plus',

'color' => 'dd4b39',

'date_ajout' => '2017-03-21'

)

),

(int) 3 => array(

'Sociale' => array(

'id' => '20',

'nom' => 'Twitter',

'lien' => 'http://twitter.com',

'image' => 'fa fa-twitter ',

'color' => '33CCFF',

'date_ajout' => '2017-03-21'

)

)

)

$contact = array(

'Contact' => array(

'id' => '7',

'nom' => 'FLEXI BORDJ',

'email' => 'contact@flexibordj.com',

'adresse' => 'lot 12 hectars Rue B N°17 Bordj Bou Arreridj',

'map' => '36.068495, 4.746334',

'fax' => '',

'tel1' => '',

'tel2' => '',

'tel3' => '',

'mob1' => '',

'mob2' => '0770281512',

'mob3' => '0770959812',

'date_ajout' => '2017-07-02'

)

)

$apropos = array(

'Apropo' => array(

'id' => '1',

'resume' => 'La Société FLEXI BORDJ à été crée en 1999 Sont activité Principale se Réside a la Fabrication

En série de Flexibles Hydrauliques et Industrielle .Destines au Marché de la Première Monte.

Reconnue tant au Niveau de BORDJ BOU ARRARIDJ que Nationale et Régional

Cette Evolution est à L’origine du au Renouvellement de nos Equipements Modernes

Fabriqué Par UNIFLEX GERMMANY.

Notre Société est Spécialisée de la Fabrication et la Commercialisation de Flexible Hydraulique Equipée ainsi les Composants Hydrauliques et Industrielles

Notre Politique Commerciale Basée sur la Qualité de nos Produits Notre Notion de Services

La Maîtressé de nos Proccèss de Fabrication Nous ont Permis de nous Développée et être Reconnus

En tant que Fournisseur chez un bon Nombre en Algérie

',

'detail' => '<p><span style="font-size:12px"><strong><a href="http://hydra-holding.com/hydra-connect/nos-produits/">Notre gamme complète</a>, combinée à notre polyvalence nous permet d’être présents dans <a href="http://hydra-holding.com/hydra-connect/nos-references/">différents domaines</a> :</strong></span><br />

<span style="font-size:14px">Matériels agricoles / travaux publics / industrie / manutention .<br />

Industrie minière, forestière et pétrolière .</span></p>

<p>FLEXI BORDJ MOBILE</p>

<p>Un Atelier Mobile Complet et très Fonctionnel nous Permet d’effectuée tous types de Dépannages</p>

<p>Sur Site a fin de Répondre a vos Problématique Techniques</p>

<p> <strong>FLEXI BORDJ </strong></p>

<p><strong> REACTIVITE – QUALITE – FLEXIBILITE </strong></p>

',

'resume1' => 'FLEXI BORDJ PLUS a été fondé en 2015 dans BORDJ BOU ARRERIDJ . Cette entreprise est un fournisseur pour le marché de tuyau et raccords hydraulique et pneumatique ainsi que un représentant et distributeur UNIFLEX spécialisé dans les machines industriels qui est aussi un partenaire préféré pour les usines des constructeurs de flexible .

',

'detail1' => '<h1><span style="font-family:Arial,Helvetica,sans-serif"><strong><span style="font-size:14px"><span style="color:#ff0000">Objectifs et visions</span></span></strong></span></h1>

<ol>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Polyvalence</strong><br />

<br />

Les presses pour flexibles UNIFLEX sont construites de manière modulaire. Il est ainsi toujours possible de réaliser les variantes les plus diverses pour satisfaire quasiment toutes les exigences et applications souhaitées.</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">Les observations du marché et les analyses des besoins du client déterminent le développement de nouveaux modules et modèles. </span></p>

<p> </p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Fiabilité</strong><br />

<br />

Les presses pour flexibles UNIFLEX sont conçues pour fonctionner de nombreuses années. La précision et la qualité de tous les produits UNIFLEX fixent les</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">critères à respecter au niveau international. Le retour des clients est enregistré afin de pouvoir déduire et</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">mettre en application des possibilités d’optimisation relatives au fonctionnement et à la disponibilité.</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">/></span></p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Innovation</strong><br />

<br />

C’est dans un dialogue permanent avec les clients</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">qu’UNIFLEX continue résolument de développer les produits existants – l’expérience est mise au profit de</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">la pratique. Les besoins du marché, les possibilités techniques innovantes et un travail approfondi de</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">recherche fondamentale donnent naissance à des produits toujours novateurs et révolutionnaires dans le</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">domaine de l'assemblage de flexibles. </span><br />

</p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Service</strong><br />

<br />

Chaque jour,</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">plus de 40 années d’expérience et de compétences sont redéfinies et transmises aux clients par UNIFLEX.</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">L’équipe UNIFLEX est chargée du conseil individuel relatif aux produits ainsi que de l’accompagnement</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">des clients, et fournit des prestations de service qualifiées telles que formations, travail logistique,</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">présentations de test et démonstration. Ainsi, vous pouvez vous concentrer sur votre activité principale, à</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">savoir la fabrication de tuyaux flexibles, en utilisant les meilleures machines disponibles sur le</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">marché.</span><br />

</p>

</li>

<li><span style="font-family:Arial,Helvetica,sans-serif"><strong>Orientation vers l’utilisateur</strong><br />

<br />

Un contact permanent</span>

<p> </p>

<p><span style="font-family:Arial,Helvetica,sans-serif">avec le client offre la possibilité de mettre en application les expérience issues de la pratique en matière</span></p>

<p><span style="font-family:Arial,Helvetica,sans-serif">de manipulation et d’opérabilité, de sécurité et d’ergonomie dans le futur développement de série.</span></p>

</li>

</ol>

<p> </p>

',

'image' => 'apropos1505333254.jpg',

'image2' => 'aproposs1505333254.jpg'

),

'Media' => array()

)

$liens = 'http://flexibordj.com'

$destintaires = array(

'contact@flexibordj.com' => 'Contact'

)

$menus = array(

(int) 0 => array(

'Menu' => array(

'id' => '1',

'nom' => 'ACCUEIL',

'controller' => 'Pages',

'action' => 'display',

'lien' => ''

)

),

(int) 1 => array(

'Menu' => array(

'id' => '2',

'nom' => 'A PROPOS',

'controller' => 'Apropos',

'action' => 'index',

'lien' => ''

)

),

(int) 2 => array(

'Menu' => array(

'id' => '4',

'nom' => 'PRODUITS',

'controller' => 'types',

'action' => 'index/1',

'lien' => ''

)

),

(int) 3 => array(

'Menu' => array(

'id' => '5',

'nom' => 'GALERIE',

'controller' => 'Albumphotos',

'action' => 'index',

'lien' => ''

)

),

(int) 4 => array(

'Menu' => array(

'id' => '6',

'nom' => 'ACTUALITES',

'controller' => 'Actualites',

'action' => 'index',

'lien' => ''

)

),

(int) 5 => array(

'Menu' => array(

'id' => '13',

'nom' => 'SERVICES',

'controller' => 'Services',

'action' => 'index',

'lien' => ''

)

),

(int) 6 => array(

'Menu' => array(

'id' => '7',

'nom' => 'CONTACTS',

'controller' => 'Contacts',

'action' => 'index',

'lien' => ''

)

)

)

$lang = 'fr'

$p = 'MACHINE UNIFLEX '

$id = '2'

$Act = array(

'Scategorie' => array(

'id' => '15',

'nom' => 'Bancs d’épreuves',

'image' => '1499605282.png',

'categorie_id' => '6'

),

'Categorie' => array(

'id' => '6',

'nom_fr' => 'MACHINE UNIFLEX ',

'image' => 'FLEXI BORDJ.jpg',

'type_id' => '2',

'date_ajout' => '2017-06-19'

),

'Souscategorie' => array(),

'Produit' => array(

(int) 0 => array(

'id' => '283',

'nom' => 'Bancs d’épreuvesP160',

'ref' => 'Bancs d’épreuvesP160',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531235118.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p> </p>

<p>Hose lines that cannot withstand the high pressure for which they are designed can cause serious damage, resulting in high costs - often higher than the price of a test bench.</p>

<p><strong>Why take a risk that can be easily avoided?</strong></p>

<p>By testing the quality of your products, you opt for safety.</p>

<p>The P 160 workshop test bench allows for the efficient and safe final inspection and testing of hose lines. It is easy to operate and quickly become part of your routine procedures.</p>

<p><span style="color:#0099ff"><strong>CARACTERISTIQUES TECHNIQUES </strong>:</span></p>

<table border="1" cellpadding="0" cellspacing="0">

<tbody>

<tr>

<td style="height:39px; width:141px">

<p><strong>Modell:</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>P 160</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Control</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Manual</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Drive</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>Druckübersetzer / Intensifier</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Flow</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>1,1 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>7 bar, 20 Nl / min</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>1590 x 795 x 370</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test bench dimension (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>2210 x 950 x 1325</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>100.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Alternative drive</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>0,38 kw, 400V 50 Hz 3Ph</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>72</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Paint</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>RAL 5012, RAL 7021</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>210 Kg empty</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="font-size:14px"><span style="color:#0099ff"><strong>Avantages : </strong></span></span></p>

<p>-Réservoir intégré avec filtre</p>

<p>- Universal</p>

<p>- CE Conforme</p>

<p>- 2 ans de garantie <!--![endif]----></p>

<p><span style="color:#0099ff"><span style="font-size:14px"><strong>Package et accessoires :</strong></span></span></p>

<p><strong> </strong></p>

<p>Un package inclut les machines sélectionnées incl. Accessoires.</p>

<p>P 160 Paquet = Machine + adaptateur « Steck O » 405.901 et 405.902, EM 10 l</p>

<p> </p>

',

'fichier' => '1531235118.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

(int) 1 => array(

'id' => '284',

'nom' => 'Bancs d’épreuves P160 Ecoline',

'ref' => 'Bancs d’épreuves P160 Ecoline',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531245590.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p>Testing has never been easier and quicker. With the P300, you can perform precision tests of hoses of up to 2500 mm in length and with pressures up to 1000 bar.<br />

<br />

Test up to 120 hoses per hour, making use of 4 parallel test lines and our quick-clamping system. You can choose between automated and manual setup mode. The P300 comes with a number of standard features such as an internal lighting and a portable power aggregate, and caters for individual test logging</p>

<p><span style="color:#0099ff"><strong>CARACTERISTIQUES TECHNIQUES </strong></span></p>

<table align="left" border="1" cellpadding="0" cellspacing="0" style="width:459px">

<tbody>

<tr>

<td style="background-color:#0099ff; height:1px">

<p><strong>Modell:</strong></p>

</td>

<td style="background-color:#0099ff; height:1px">

<p><strong>P 300</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:1px">

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Control</strong></p>

</td>

<td style="height:1px">

<p><strong>Control B + Touch</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Drive</strong></p>

</td>

<td style="height:1px">

<p><strong>Hydraulic aggregate 3kW with intesifier</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Flow</strong></p>

</td>

<td style="height:1px">

<p><strong>13 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:1px">

<p><strong>400-50-3 (VAC) </strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:1px">

<p><strong>3750 x 2400 x 870 </strong></p>

</td>

</tr>

<tr>

<td style="height:37px">

<p><strong>Tank dimension closed (mm)</strong></p>

</td>

<td rowspan="1" style="height:1px">

<p><strong>3750 x 1450 x 870 </strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Test bench dimension (mm)</strong></p>

</td>

<td style="height:1px">

<p><strong>-</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Aggregate dimension (mm</strong></p>

</td>

<td style="height:1px">

<p><strong>830 x 740 x 1340</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td rowspan="1" style="height:1px">

<p><strong>140.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Alternative drive</strong></p>

</td>

<td rowspan="1" style="height:1px">

<p><strong>-</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:1px">

<p><strong>70</strong></p>

</td>

</tr>

<tr>

<td style="height:59px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:59px">

<p><strong>1000 Kg</strong></p>

</td>

</tr>

<tr>

<td style="height:1px">

<p><strong>Weight aggregate</strong></p>

</td>

<td style="height:1px">

<p><strong>200 Kg</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="color:#0099ff"><strong>Avantages : </strong></span></p>

<p>-Sans lubrification</p>

<p>-Universal</p>

<p>-CE Conforme</p>

<p>-2 ans de garantie</p>

<h3><span style="color:#0099ff"><strong>Package et accessoires</strong></span></h3>

<p>Développez cette machine à tout moment en utilisant les accessoires suivants:</p>

<h4> UTS</h4>

<h4><strong><a href="https://www.uniflex-hydraulics.com/fr/produits/accessoires/btr-ctrl-c/?tt_products%5BbackPID%5D=44"><span style="color:#000000">BTR Ctrl C</span></a></strong></h4>

<p> </p>

',

'fichier' => '1531246295.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

(int) 2 => array(

'id' => '285',

'nom' => 'Bancs d’épreuves P200',

'ref' => 'Bancs d’épreuves P200',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531247260.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p>Der The P 200 test bench with digital Control B+ Touch control and tight clamping system makes testing not only easier and quicker but also extremely flexible. Enter all test parameters at the user-friendly menu control and save them, if required with the relevant product number.</p>

<p>The test parameters for a product can then be reloaded at the push of a button, reducing tooling time while ensure reproducibility.</p>

<p>The patented tight clamping system does away with screws and threaded adapters. Pressure testing reveals any defects in the material or assembly at the earliest possible time</p>

<p><strong>CARACTERISTIQUES TECHNIQUES </strong>:</p>

<table border="1" cellpadding="0" cellspacing="0">

<tbody>

<tr>

<td style="height: 39px; width: 141px; background-color: rgb(0, 153, 255);">

<p><strong>Modell:</strong></p>

</td>

<td style="height: 39px; width: 149px; background-color: rgb(0, 153, 255);">

<p><strong>P 160</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>150 - 1300 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Control</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Control B + Touch</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Drive</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>Druckübersetzer / Intensifier</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Flow</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>5 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>7 bar, 20 Nl / min</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>1590 x 795 x 370</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test bench dimension (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>2210 x 950 x 1325</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>100.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Alternative drive</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>0,38 kW</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>72</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Paint</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>RAL 5012 ; RAL 7021</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>210 Kg empty</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="color:#0099ff"><strong>avantage:</strong></span><br />

-universal</p>

<p>-Réservoir intégré avec filtre</p>

<p>- CE Conforme</p>

<p>- 2 ans de garantie <!--![endif]----></p>

<p> </p>

<p><span style="font-size:14px"><span style="color:#0099ff"><strong>Package et accessoires :</strong></span></span></p>

<p><br />

Un package inclut les machines sélectionnées incl. Accessoires.</p>

<p>P 200 Paquet = Machine + BDSP, HS 400, EM 10 l + DS + DSP</p>

',

'fichier' => '1531247260.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

),

(int) 3 => array(

'id' => '286',

'nom' => 'Bancs d’épreuves P300',

'ref' => 'Bancs d’épreuves P300',

'scat_id' => '0',

'categorie_id' => '0',

'date_ajout' => '2018-07-10',

'image' => '1531255802.png',

'utilise_fr' => '<table align="left" border="02" cellpadding="0" cellspacing="0" style="width:354px">

<tbody>

<tr>

<td>

<p>Test pressure:</p>

</td>

<td>

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

</tbody>

</table>

<p> </p>

<p> </p>

<p>Testing has never been easier and quicker. With the P300, you can perform precision tests of hoses of up to 2500 mm in length and with pressures up to 1000 bar.<br />

<br />

Test up to 120 hoses per hour, making use of 4 parallel test lines and our quick-clamping system. You can choose between automated and manual setup mode. The P300 comes with a number of standard features such as an internal lighting and a portable power aggregate, and caters for individual test logging</p>

<p><strong>CARACTERISTIQUES TECHNIQUES </strong>:</p>

<table border="1" cellpadding="0" cellspacing="0">

<tbody>

<tr>

<td style="height: 39px; width: 141px; background-color: rgb(0, 153, 255);">

<p><span style="color:#000000"><strong>Modell:</strong></span></p>

</td>

<td style="height: 39px; width: 149px; background-color: rgb(0, 153, 255);">

<p><span style="color:#000000"><strong>P 300</strong></span></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test pressure</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>100 - 1000 bar</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Control</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Control C.2 + Touch</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Drive</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>Hydraulic aggregate 3kW with intesifier</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Flow</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>13 l/min.</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>400-50-3 (VAC)</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Tank dimension (mm)</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>3750 x 2400 x 870</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Tank dimension closed (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>3750 x 1450 x 870</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Aggregate dimension (mm)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>830 x 740 x 1340</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Reservoir capacity</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>140.00 l</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Volume (dBA)</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>70</strong></p>

</td>

</tr>

<tr>

<td style="height:39px; width:141px">

<p><strong>Paint</strong></p>

</td>

<td style="height:39px; width:149px">

<p><strong>RAL 5012, RAL 7021</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Test Medium</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>Test Oil</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Max. hose length</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>2500 mm</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight tank dimension</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>1000 Kg empty</strong></p>

</td>

</tr>

<tr>

<td style="height:42px; width:141px">

<p><strong>Weight aggregate</strong></p>

</td>

<td style="height:42px; width:149px">

<p><strong>200 Kg empty</strong></p>

</td>

</tr>

</tbody>

</table>

',

'cara' => '<p><span style="color:#0099ff"><strong>Avantages : </strong></span></p>

<p>- Réservoir intégré avec filtre</p>

<p>- Universal</p>

<p>- CE Conforme</p>

<p>- 2 ans de garantie</p>

<p> </p>

<p><span style="color:#0099ff"><strong>Package et accessoires :</strong></span></p>

<p>Développez cette machine à tout moment en utilisant les accessoires suivants:</p>

<p><strong>BTR Ctrl C/UTS</strong></p>

',

'fichier' => '1531255802.pdf',

'titrepg' => '',

'scat1_id' => '15',

'scat2_id' => '0'

)

),

'Media' => array()

)

$k = (int) 0

include - APP/View/Produits/index.ctp, line 29

View::_evaluate() - CORE/Cake/View/View.php, line 971

View::_render() - CORE/Cake/View/View.php, line 933

View::render() - CORE/Cake/View/View.php, line 473

Controller::render() - CORE/Cake/Controller/Controller.php, line 960

Dispatcher::_invoke() - CORE/Cake/Routing/Dispatcher.php, line 200

Dispatcher::dispatch() - CORE/Cake/Routing/Dispatcher.php, line 167

[main] - APP/webroot/index.php, line 114